When it comes to the recycling industry, Bronneberg stands out as a global leader renowned for its innovative technology, quality, and reliability. Among its wide range of recycling solutions, Bronneberg’s optical sorting technology is a game-changer. But what exactly is optical sorting, and why is it so crucial for the recycling process?

Refine the Purity of your Material

Bronneberg is taking Optical Sorting to a new level

What is Optical Sorting?

Optical sorting is an automated method of sorting solid products using cameras and sensors to distinguish materials based on their optical properties. This technology scans items and separates them according to various criteria like color, shape, size, and composition. The roots of optical sorting technology trace back to early agricultural processes where it was used to sort grains and seeds. Over the years, it has evolved significantly and now plays a vital role in recycling and waste management.

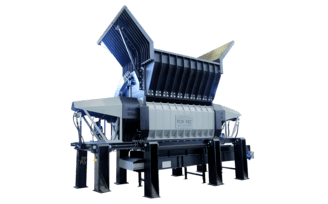

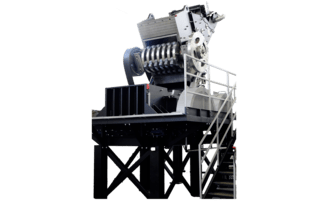

Bronneberg's Role in Recycling

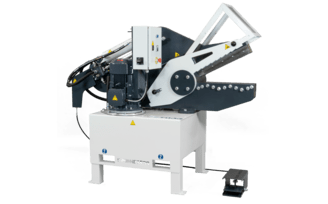

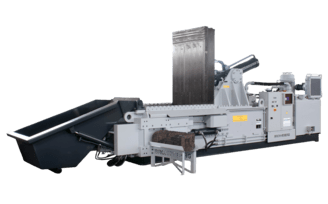

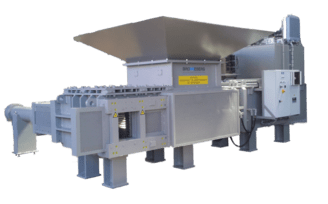

Bronneberg has a rich history in the recycling industry, known for delivering innovative recycling solutions. From the beginning, Bronneberg has grown into a worldwide known manufacturer, offering machines that handle everything from small cable strippers to large scrap metal balers and shears. Our commitment to innovation and quality has made us a trusted name in the market.

The Technology Behind Optical Sorting

Optical sorting technology operates on the principles of advanced camers. Here’s a breakdown of how it works:

- Vibrating table & Belt: The material is spread out on a vibrating table and then transported by a high-speed belt.

- Imaging Systems: High-speed cameras capture images of items as they pass through the light beam.

- Processing Units: Data from the sensors is analyzed in real-time to determine the sorting criteria.

- Ejection Mechanisms: Based on the analysis, precise ejection mechanisms (air jets) separate the items into different categories.

Applications of Bronneberg Optical Sorting Machines

Bronneberg’s machines are versatile and can be used in multiple recycling applications, such as:

- Scrap Metal Recycling: Separates different types of metals for efficient recycling.

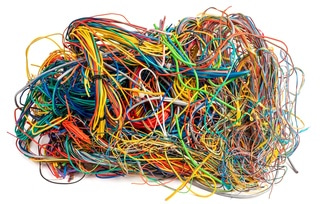

- Cable Recycling: Separates the copper and aluminium granulate.

- WEEE Recycling: Separation of Print-Plates

Maintenance and Support Services

Regular maintenance is crucial to keep optical sorting machines running efficiently. Bronneberg offers support services, including installation, maintenance, spare parts, and technical assistance. This ensures that your machines remain in optimal condition and minimize downtime.

Conclusion

With this new innovation, we offer our customers revolutionary solutions to upgrade their recycling process. We offer total solutions to our customers. Contact us and talk with one of our specialist about your recycling business's needs.