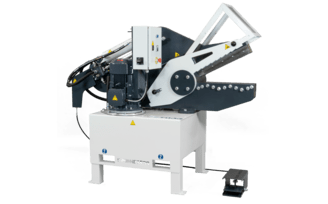

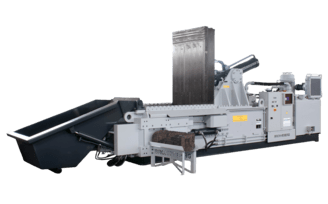

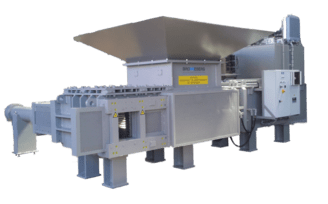

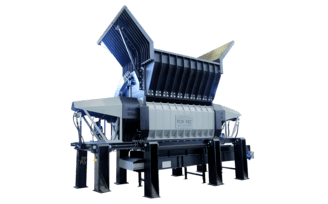

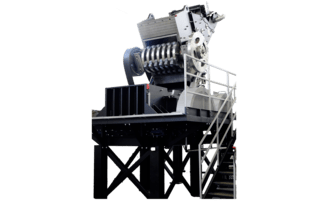

With years of experience in the recycling market, Bronneberg develops and produces metal balers of the highest quality. Balers are widely used in the metal recycling industry to compress metal or aluminum, reducing the volume. Scrap presses are efficient, safe, and robust. In this article, we will take a closer look at the operation and benefits of metal balers.

Operation of Scrap Balers

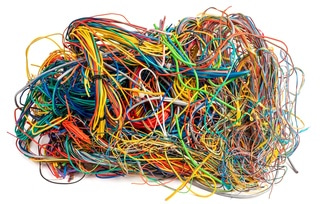

Metal Balers operate with the use of hydraulic pressure. The metal waste to be recycled is placed in the press chamber and compressed into a compact mass with the use of a hydraulic cylinder. This compact mass can then be transported to the steel mill to be melted down into new products. There are different versions of scrap balers, which also determine the package size. For example, there are presses for 20x20, 30x30 and 40x40 packages available.

Advantages of a Scrap Baler

The use of Metal Balers has several advantages:

- Efficiency: Scrap Balers can efficiently compress large amounts of metal scrap into compact packages.

- Safety: Bronneberg Balers are designed with safety in mind and have various safety features to prevent accidents.

- Environmentally friendly: Scrap presses contribute to a sustainable future by recycling metal waste. The materials can be reused by melting it. In addition, the number of transports is reduced by reducing the volume of the material.

- Cost-saving: By compressing metal waste, transport can be saved due to smaller volumes.

What Metal Baler do I need?

When choosing the scrap press that fits your business needs, there are several factors to consider, including:

- The size of the pressing chamber

- The type of material being processed

- The desired capacity

- The available space

- The budget

Contact us and talk to our specialists which baler is suitable for your recycling needs!

View our product range of Metal Balers on our product page. Also, have a look at our used metal balers!