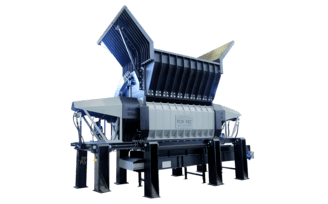

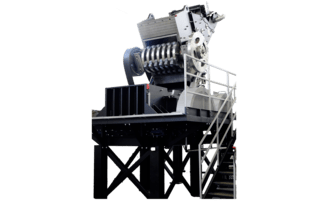

Bronneberg co-operates with the leading European and North American manufacturers of ferrous and non-ferrous recycling machines and installations. We are able to offer complete recycling solutions, that match specific customer demands and the waste stream that needs to be processed and transported. Bronneberg always strives for the best quality and highest possible recovery rates and outputs.

Recycling Solutions & Equipment

We are able to offer complete recycling solutions, that match specific customer demands and the waste stream that needs to be processed and transported.

Metal recycling

Many are surprised to come to know that steel is the World’s most recycled material. Scrap metal can be recycled and re-used again for an indefinite number of times. Recycling metals means preserving some of the nature’s most limited resources. Scrap metal originates both in business and residential environments. Unlike waste, metal scrap has a monetary value and the steel industry has been actively recycling various metals for more than 150 years. The metal recycling industry encompasses a wide range of metals. The more frequently recycled metals are scrap steel, iron (ISS), lead, aluminium, copper, stainless steel and zinc. There are two main categories of metals: Ferrous metals: which contain iron; Non-Ferrous: metals without iron. Non-ferrous metals also include a wide range of precious (gold, silver, platinum, etc) and exotic metals (mercury, tungsten, bismuth etc.). Recycling ferrous scrap metal is beneficial to the World’s environment. Besides the fact that it is much cheaper to recycle ferrous metal than to mine virgin ore, the following important advantages are: - 75% savings in energy; - 90% saving in raw materials used; - 86% reductions in air pollution; - 40% reduction in water use; - 76% reduction in water pollution. In a “greenhouse” gas constrained future, energy is one of the most important benefits of metal recycling. Energy savings from recycling non-ferrous metals: - Aluminium: 95% - Copper: 85% - Lead: 65% - Zinc: 60%

Aluminium Recycling

Key Facts About Aluminium As the most universally used non-ferrous metal, aluminium’s popularity relies on its weight, elasticity and corrosion resistance. Its top industrial uses are in the manufacturing of consumer products, transportation and electrical. Unlike steel and copper, it weighs over 2 thirds less which makes it a great candidate in the automotive and aerospace industry. Although more expensive and not as strong as steel, aluminium is a great electricity conductor, so it’s widely used to manufacture electric wires and cables. Why Is The Recycling of Aluminium Important? The recycling of aluminium effectively dates back to the time when people started manufacturing aluminium. One of the main reasons for the recycling of aluminium is that it's fairly simple to melt. At the same time, recycling doesn’t alter aluminium’s quality, so the process can be repeated unlimitedly. In contrast to the use of new raw materials, there is a 95% energy saving rate when aluminium scrap is being used for the production of new aluminium, so recycling it provides a safe and efficient way to continue using it without tapping into natural resources. Best Equipment To Recycle Aluminium Because of this high rate of energy saving turnover, the ultimate goal while recycling aluminium is to achieve the purest end fraction. This material will be oversupplied back to the aluminium smelter and melt losses can be minimised. Bronneberg offers an extensive range of aluminium recycling machinery and equipment, including the following selection of solutions: XRF and LIBS handheld metal analysing devices for the sorting of various aluminium alloys; Alligator shears for cutting and cleaning aluminium profiles; Metal balers for compacting scrap aluminium into bales with high density That can be directly fed into the furnaces; Single-shaft shredders and rotary shears for the processing of contaminated aluminium scrap; Hammer Mills to densify and clean aluminium scrap; Eddy-current non-ferrous metal separators for the recovery of aluminium from municipal solid waste (MSW) For more information on aluminium recycling, take a look at our full guide. If you would like to benefit from our experience in the field of aluminium recycling, please contact one of our specialists Alternatively, find out more about how to recycle different types of metal with this three-step guide.

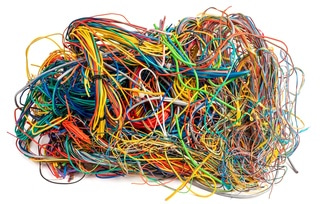

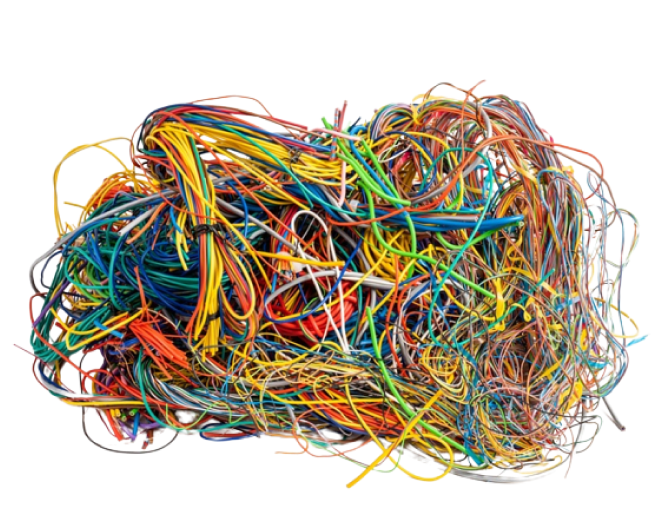

Cable Recycling

Our specialists have over 40 years of experience in the field of cable recycling, such as recycling old copper and aluminium cables. Where in the past the cable was set on fire to separate the copper and aluminium, today our cable recycling equipment is essential in the global cable recycling industry. Cable recycling stripping machines Bronneberg manufacturers in-house a complete range of cable recycling machinery, such as copper cable stripping machines, sold all over the world through an extensive dealer network. The Bronneberg cable recycling machines are highly usable and meet the latest safety and engineering requirements. These aspects are combined with the highest production capacities in the market. Our selection of cable recycling machines varies, from small bench top cable strippers to heavy duty cable stripping machines for the processing of steel armoured underground and “submarine” cables. Cable recycling granulators Bronneberg cable recycling machinery also includes a complete selection of cable granulation systems. This range of cable processing equipment starts with small compact copper wire granulators and ends with big turnkey cable recycling machines capable of processing over 5.000 Kg per hour. Our complete range of cable granulation systems is based on proven techniques, which include pulverising mills for the processing of flexible copper wires and sieving systems to separate the last copper (dust) fraction for PVC granules. At Bronneberg, we know how to achieve the highest copper recovery rates in the market. Moreover, our recycling machine range includes a wide variety of different types of pre-shredders (single shaft shredders and rotary shears), feeding bunkers, conveyor belts, magnetic separators and dust filtration systems. If you would like to benefit from our experience in the cable recycling field and machinery, please contact one of our specialists. We will be happy to help you. Bronneberg provides flexible recycling solutions. Don’t hesitate to take a look at our range of recycling machinery and used recycling machines we offer for sale.

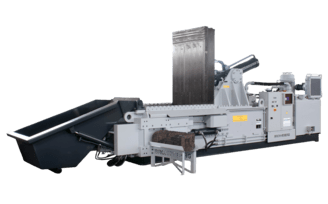

ELV Recycling

Does your ELV (cars) recycling business process require a car baler that runs faultlessly day in, day out? Are you looking for a car baler that is not only suitable for crushing stripped-out car chassis but also for compacting high-volume scrap? Bronneberg offers an extensive range of car balers and car flatteners with horizontal and angled infeeds, which can be installed at any location. We also supply car balers in our capacity as an exclusive dealer for well-known brands

WEEE Recycling

WEEE stands for Waste Electrical and Electronic Equipment. In the Netherlands, a country with roughly 17 million inhabitants, every year more than 100 million kilograms of this material are being collected. Due to the high levels of toxic substances found in electrical and electronic devices, WEEE legislation was implemented to regulate business operations and educate the general public on the importance of correct recycling procedures and use of suitable equipment. For this reason, Bronneberg’s comprehensive product range also includes machines for the processing of outdated and faulty electronic devices. WEEE scrap roughly contains the following materials: Iron (30%) Non-ferrous metals (15%) Plastics (35%) Printed circuit boards (5%) Electric motors and cables (5%) Other materials, and batteries (10%) Bronneberg specialises in turnkey recycling installations for the professional processing of WEEE scrap, utilising our innovative WEEE recycling equipment and machinery. We are able to advise you on the various types of machines which are necessary for the mechanical size reduction of WEEE scrap and the effective separation of the different material streams, crucial for ensuring WEEE compliance. By embedding a Bronneberg WEEE recycling plant, you are able to generate secondary raw materials from old electronic devices and you will contribute to a sustainable economy. If you want to learn more about the complete range of machines for the processing of WEEE scrap, feel free to contact one of our experts.

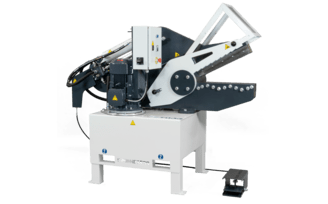

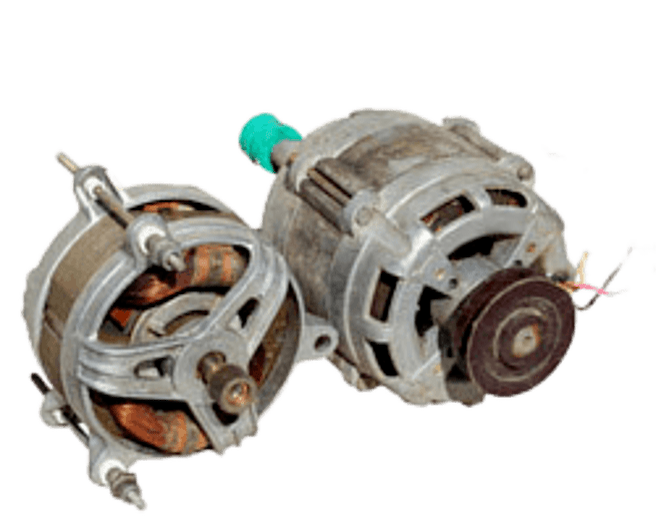

Electric motor recycling

Are you searching for an easy but profitable way for electric motor recycling to recycle scrap electric motors for example? Bronneberg is able to provide you with the perfect recycling machine to do this; There are a lot of electric motors recycling companies but Bronneberg excels in this because they are specialized in recycling and our car engine wrecker is the machine to start making money today. Our engine wrecker is simple to operate and built to last.

Paper Recycling

Paper and cardboard are the materials for a circular economy. 84% of the paper and cardboard that is placed on the market is collected and reused. Recycling of paper and cardboard is part of the sustainability challenge. Reuse reduces the use of new raw materials, prevents waste and ensures that CO2 is stored longer in paper and cardboard. Bronneberg supplies a wide range of machines for recycling paper. If you want more information about the complete range of machines for processing paper, please contact one of our specialists without obligation. We are happy to inform you about the latest developments.

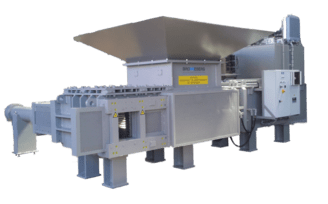

Refrigerator Recycling

Every day, tens of thousands of refrigerators and cooling systems are being recycled in Europe. Refrigerator recycling is a separate specialty because of harmful gases such as CFC’s which could be released into the atmosphere while recycling old fridges. CFC emission is one of the causes of the greenhouse effect (global warming). A refrigerator contains approximately the following recyclable materials: Iron (62%) Non-ferrous metals (6%) Plastics (16%) Polyurethane (10%) The refrigerator recycling process can be divided into the following steps: Manual removal of the CFC gas Manual removal of electrical cable, glass and compressor Mechanical treatment of the refrigerator by means of the recycling plant Bronneberg specialises in turnkey recycling installations for the professional processing of refrigerators. We are able to advise you on the various types of machines which are necessary for the mechanical processing of the refrigerators and the effective separation of the different material streams. The main components in a refrigerator recycling plant are: Single-shaft hydraulic driven shredder or hydraulic driven rotary shear for primary size reduction A hammer mill which will further clean and densify the material coming from the pre-shredder Neodymium magnets and Eddy current separators for the separation of ferrous and non-ferrous metals Dust filterComplete Recycling Solutions and Equipment

Bronneberg provides a full range of recycling services and machinery for different types of metal and paper waste, including commercial and industrial materials.

Whether you’re looking for WEEE recycling equipment, or machines that can process aluminium, electric motors and ELVs, we can help. We have over 40 years of experience in the manufacturing of recycling solutions and we’re also exclusive dealers for other world-renowned brands.

Bronneberg recycling equipment has been manufactured using state of the art technology, providing you with comprehensive recycling solutions to suit your needs. Our goal is to deliver reliable products that can handle a variety of waste streams and reduce overhead costs.